Sandblasting and Surface Preparation

What is Sandblasting?

Sandblasting, or abrasive blasting, is an essential process

for cleaning surfaces and preparing them for further treatment. This technique

effectively removes contaminants such as rust, old paint, and other debris from

various materials, including metal, brick, and concrete. Additionally,

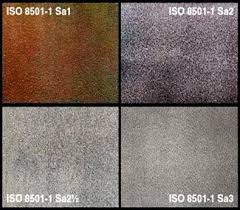

sandblasting etches a fine pattern on the surfaces, creating a specific profile

that enhances the adhesion of subsequent coatings. The surface profile,

measured in microns, is determined by assessing the distance between the

highest peaks and the lowest valleys, ensuring optimal preparation for the

coating process.

Why We Sandblast

The primary objective of sandblasting is to meticulously

prepare surfaces for subsequent treatments such as painting and coating. This

process is vital for more than just cleaning; it removes contaminants that

could hinder the bond between the substrate and the coating. Additionally,

sandblasting creates a specific surface profile that increases the surface

area, enhancing the mechanical adhesion of the coating. This precise

preparation is crucial for ensuring the strong adhesion of protective coatings,

which significantly contributes to the durability and longevity of the

coatings. Effective sandblasting prevents premature peeling and flaking,

thereby playing an indispensable role in the preservation and enhancement of

any asset.

How Sandblasting Works

A sandblasting pot requires two things, abrasives or media

and a whole lot of air. Abrasive materials are introduced to a stream of

compressed air and sent down a blast hose before finally being narrowed down

into a nozzle with a smaller opening. At Industrial Services Victoria, the

machines we use are designed to regulate this abrasive force with precision. We

utilize a variety of media, surprisingly not one of which is sand these include

garnet, steel grit, and glass bead, in different sizes to achieve the specific

profile needed for each project. We talked about needing a whole lot of air sandblasting

requires substantial air flow; fortunately, our robust 400cfm compressor is

well-equipped to support this demanding process.

The Importance of Quality Sandblasting

Poorly executed sandblasting can lead to a range of problems — from uneven surfaces that lead to poor coating adhesion, to overblasting which can weaken the structural integrity of the material. Our expertise ensures that sandblasting is done correctly, maintaining the balance between thorough cleaning and preserving the strength of the substrate.

Our Location

Industrial Services Victoria is strategically located in

Carrum Downs, easily accessible from both EastLink and Peninsula Link, with

facilities designed to accommodate semi-trailers. This accessibility allows for

efficient transport and handling of large-scale projects, making it convenient

for our clients to get their needs met quickly and effectively.